Green Advanced Technology

R&D

Technical data

We are running towards the world's best through continuous technological improvement.

Comparison of Zinc Plating, Zn-Ni plating and Zn-Flake Coating

Zn plating + Chromate

Zn-Ni Plating + Chromate

Zinc Flake Coating

Advantages

- Low cost

- Good appearance

- Better corrosion resistance compared to Zn plating

- NSST: 1000hrs at 15㎛, with Chromate treatment

- Good appearance

- High ardness of plating layer

- High corrosion resistance at lower thickness (8㎛ : NSST 1000hrs.)

- No hydrogen embrittlement

- Simple coating process

- No waste water

- Good resistance to galvanic corrosion

- No harmful heavy metal (Cr, Ni, ect)

- High heat resistance

Weakness

- Low corrosion resistacne

- Waste water

- Weak wear resistance

- Hydrogen embrittlement risk

- Complicated coating process

- Weak to humidity

- Chromate treatment required for corrosion resistance

- Waste water

- Ni ion releasing risk

- Hydogen embrittlement risk

- Complicated coating process

- High cost

- High curing Temperature(250~340℃)

- Relatively poor appearance

- Lower hardness than Zn-Ni plating

Zn plating + Chromate

Advantages

- Low cost

- Good appearance

Weakness

- Low corrosion resistacne

- Waste water

- Weak wear resistance

- Hydrogen embrittlement risk

- Complicated coating process

- Weak to humidity

Zn-Ni Plating + Chromate

Advantages

- Better corrosion resistance compared to Zn plating

- NSST: 1000hrs at 15㎛, with Chromate treatment

- Good appearance

- High ardness of plating layer

Weakness

- Chromate treatment required for corrosion resistance

- Waste water

- Ni ion releasing risk

- Hydogen embrittlement risk

- Complicated coating process

- High cost

Zinc Flake Coating

Advantages

- High corrosion resistance at lower thickness (8㎛ : NSST 1000hrs.)

- No hydrogen embrittlement

- Simple coating process

- No waste water

- Good resistance to galvanic corrosion

- No harmful heavy metal (Cr, Ni, ect)

- High heat resistance

Weakness

- High curing Temperature(250~340℃)

- Relatively poor appearance

- Lower hardness than Zn-Ni plating

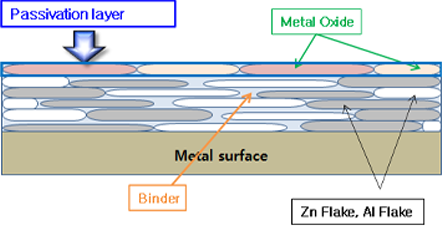

Zn-Al Flake Coating Anticorrosion Mechanisms

Corrosion

resistance

resistance

Sacrificed

Protection

Protection

Passivation

Self healing

Effect

Effect

Baarrier

Effect

Effect

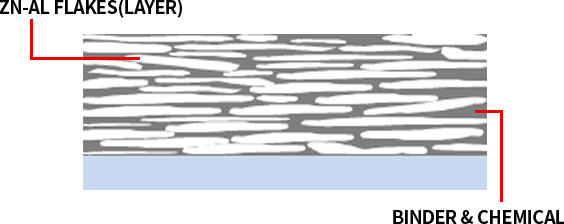

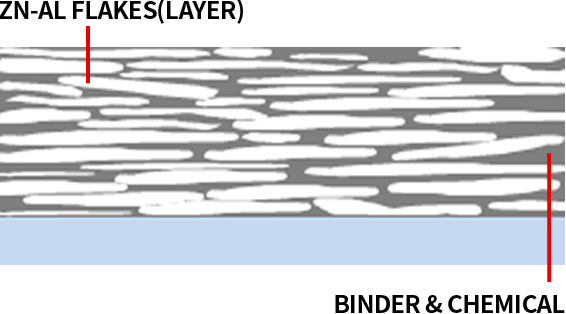

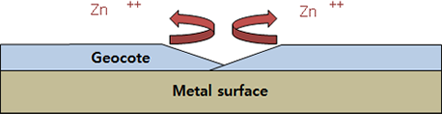

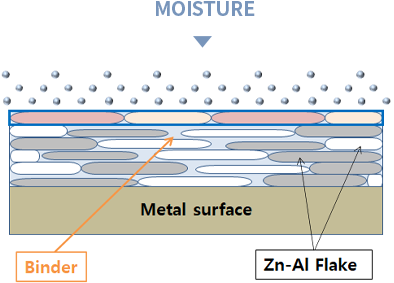

GEOCOTE™ Base Coat Anticorrosion Mechanisms

Sacrificed Protection

- It is a sacrificial protection structure that protects iron material by preventing ionization of iron by firstly oxidizing Zn and Al which have higher ionization tendency than iron material.

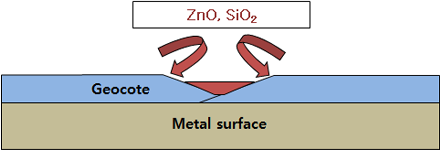

Passivation

- Plating is when Zn is oxidized, Zn is converted to ZnO and the plating layer disappears.

- In the case of S-570, the binder component contains oxides of Zn and Al and forms a metal oxide layer (passivation film) on the surface of the coating film

- Further, since the binder component surrounds the surfaces of Zn and Al, there is also an effect of retarding the oxidation of Zn and Al.

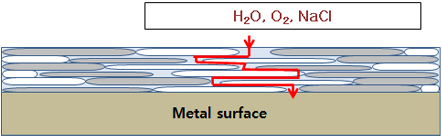

Barrier effect

- Zinc flake coating structure makes it more difficult for the aggressive substances such O2, H2O, NaCl, etc..to reach the steel surface (longer way)

Self healing effect

- The oxide of Zn and Al expands more than before the oxidation, and the oxide reacts with the binder component to complement the binding site.

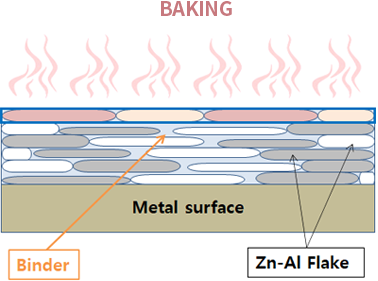

GEOCOTE™ MT, RT

Zinc-Al Flake Coating

- Thermal curing System (250~360°C Baking)

- Dip-Spin or Spray, 2Coating 2Baking

GEOCOTE™ MT

- Room temperature curing System

- Lacquer or Spray